Construction material makes a difference! Triol heat exchangers are made of stainless steel.

Today we are going to tell you about the specifications and the differences of the Triol heat exchanger used in VSD design.

The heat exchanger for the AK06 VSD is made of a special stainless steel material.

Let's talk a little about the work of the heat exchanger and why the material it is made from is so important. When the VSD operates it produces heat, but the heat exchanger with the lamellas helps to cool it down.

All heat exchangers are tested by water flow for their hermeticity.

Thanks to Triol's development, the design of the heat exchanger allows a better result with smaller dimensions, which is ensured by the special lamellae.

Our heat exchanger allows more heat to be cooled with smaller dimensions compared to standard solutions used by competitors. If we had used a standard heat exchanger, its dimensions would have been twice as large, which leads to a great size and weight of the station, which is important for many factors, such as transportation, the availability of space for the station, and the location, for example, on an offshore platform where every cm and kg plays a role.

The hot air is cooled by the design of the lamellas and the material from which they are made.

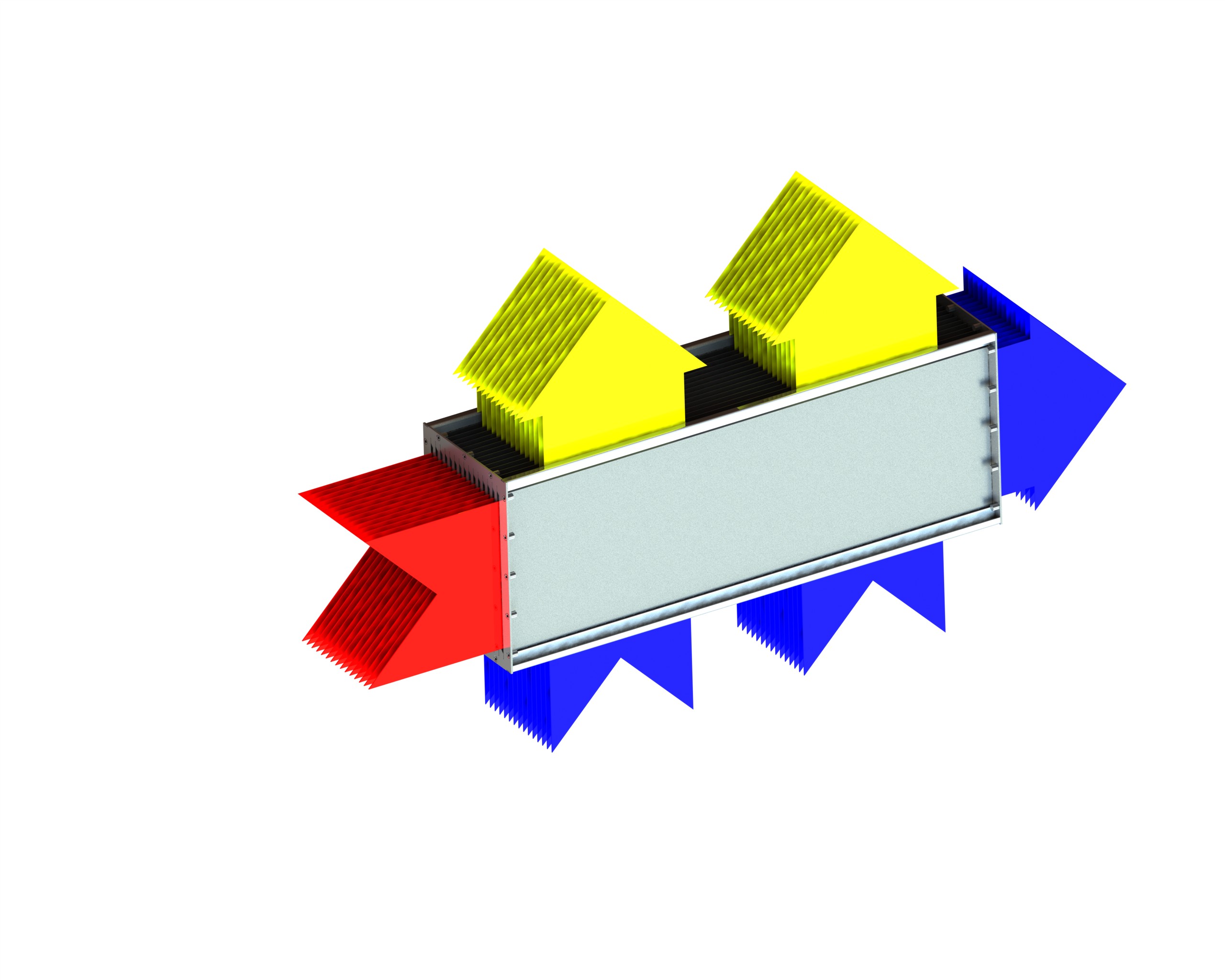

Figure 1 shows a diagram of the VFD cooling by means of the heat exchanger:

Hot air flows inside the heat exchanger due to cooling by the lamellas inside the VSD. The hot air contacts the cold side of the lamellas and cools the working elements of the drive.

Triol uses laser welding to weld stainless steel components; this type of welding is a difficult, expensive and high-tech process.

In order to avoid corrosion on the surface of stainless steel and to reduce the strength of the part, additional post-welding treatment is required as a matter of course.

We use passivation as a post-treatment of seams after welding. We appy chromium oxide on the surface of the workpiece to create a protective coating against corrosion.

The number of lamellae in the heat exchanger may vary and depends on the capacity of the VSD, the area of the cooled surface and the amount of heat released from the operating elements of the VSD.

The standard version of the heat exchangers is 304 stainless steel, but for marine versions 316 acid-resistant stainless steel is used.

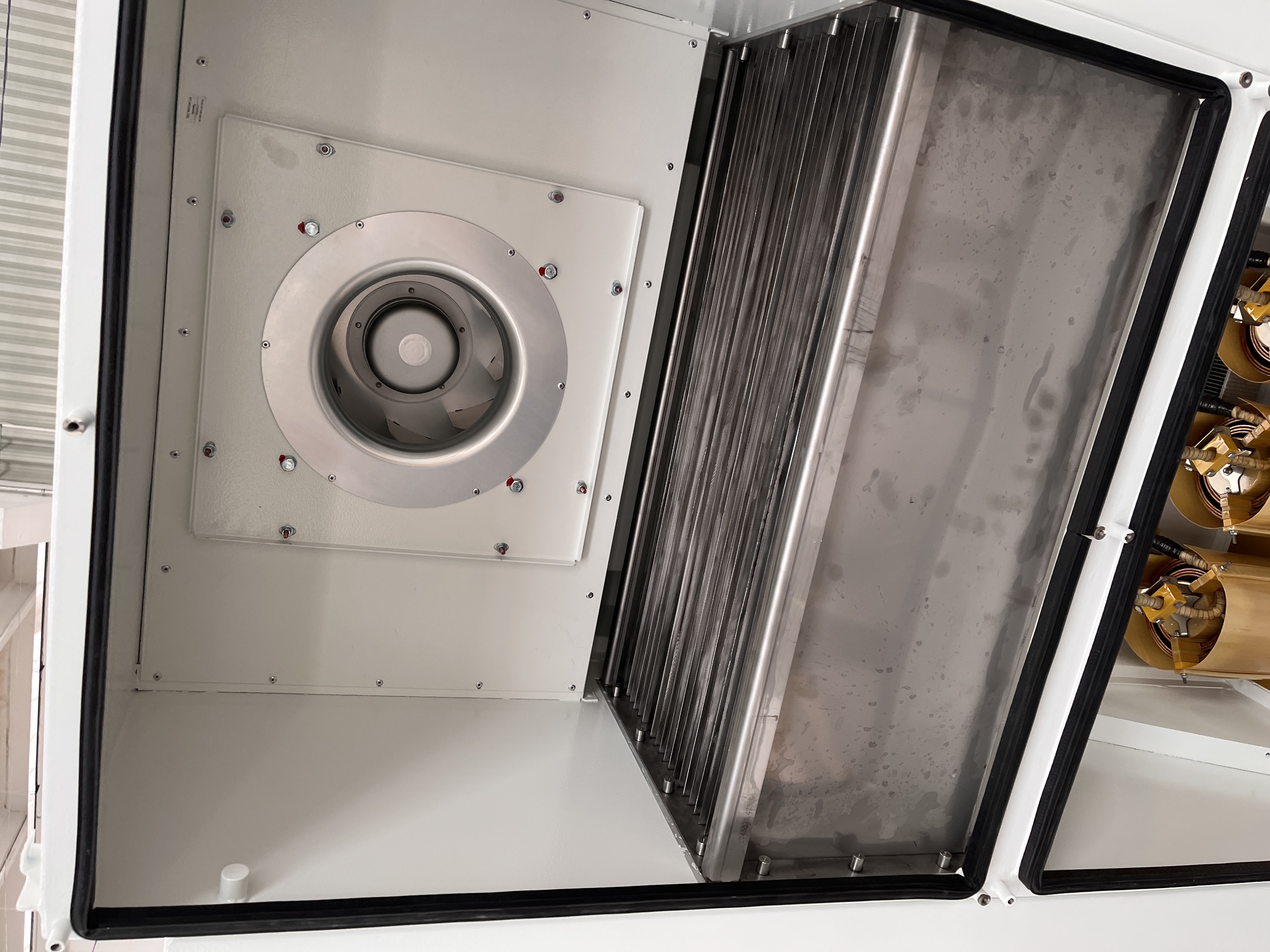

In this photo you can see the heat exchanger already installed in the VSD.

Triol uses its own developments to improve the quality of equipment at customer sites, as well as applies high-tech processes and quality materials!

Apply Triol Equipment - Work with professionals!

subscribe.el.title

- Product news

- Events

- Discounts

1(405)6157755 (Business)

1(405)6157755 (Business)

Google

Google